Understanding Industry Trends: Innovations in Coating Inspection Technology

Introduction to Coating Inspection Technology

In the rapidly evolving world of industrial technology, coating inspection plays a crucial role in ensuring the quality and longevity of materials. This process involves examining protective coatings on various surfaces to prevent corrosion, wear, and other forms of degradation.

With advancements in technology, the methods and tools for coating inspection have seen significant innovations. Understanding these industry trends is essential for businesses aiming to maintain high standards of quality and safety.

Advancements in Non-Destructive Testing (NDT)

One of the most significant innovations in coating inspection technology is the advancement of non-destructive testing (NDT) methods. These techniques allow inspectors to evaluate the condition of coatings without causing any damage to the material.

Modern NDT methods include ultrasonic testing, magnetic particle testing, and radiographic testing. These techniques offer precise and reliable results, making them invaluable in industries where safety and durability are paramount.

Ultrasonic Testing

Ultrasonic testing uses high-frequency sound waves to detect imperfections in coatings. This method is particularly effective in identifying thickness variations and internal defects, ensuring the coating's integrity.

Digital Solutions and Automation

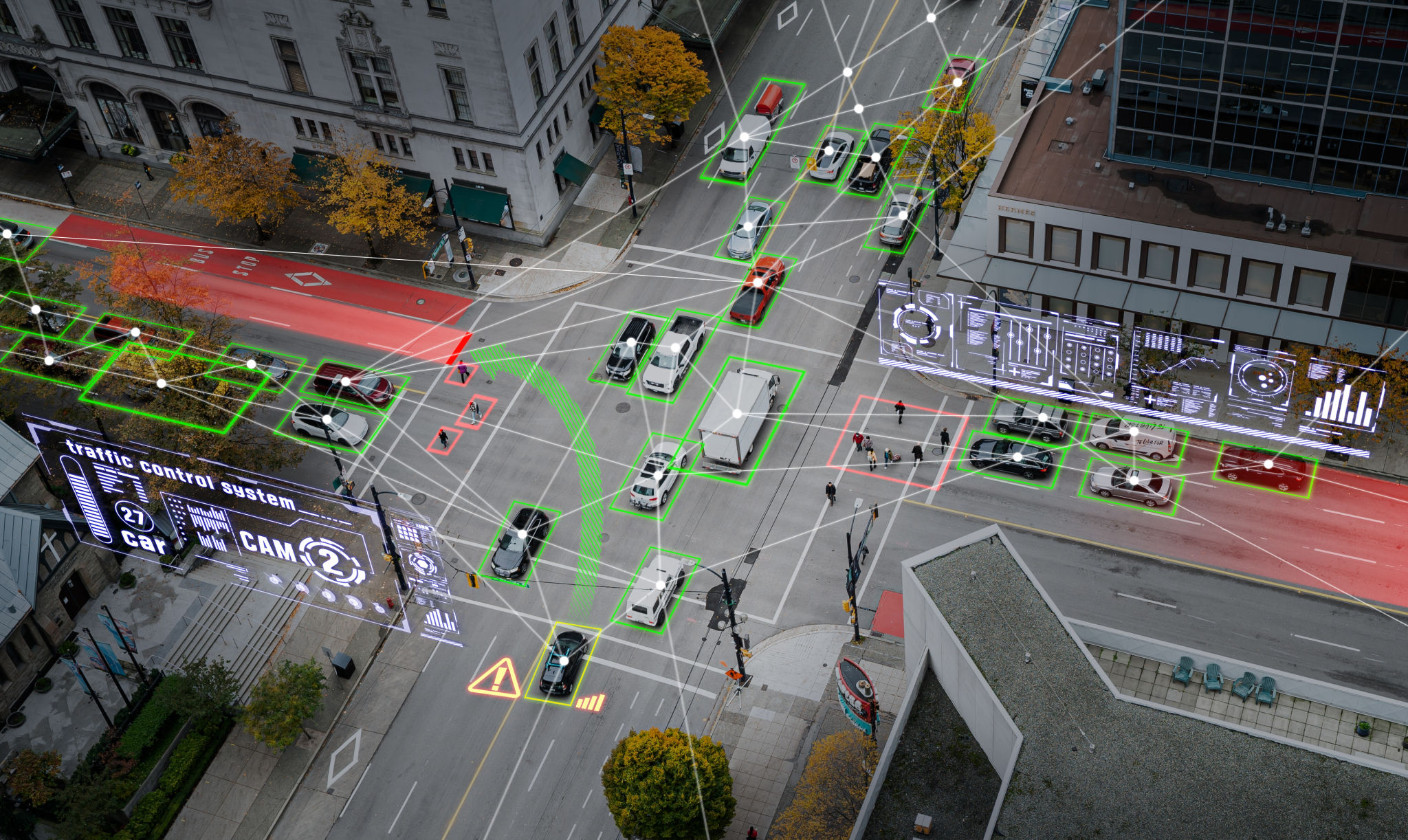

The integration of digital solutions and automation has transformed the coating inspection landscape. Digital tools enable real-time data analysis, improving accuracy and efficiency in inspections.

Automated systems, equipped with advanced sensors and software, can perform inspections with minimal human intervention. This not only reduces the risk of human error but also speeds up the process significantly, saving time and resources.

Use of Drones

Drones are increasingly being used for coating inspections, especially in hard-to-reach areas. They can capture high-resolution images and videos, providing detailed insights into the condition of coatings.

Integration with the Internet of Things (IoT)

The Internet of Things (IoT) has brought a new dimension to coating inspection. IoT devices can continuously monitor the condition of coatings and send real-time data to cloud-based platforms for analysis.

This continuous monitoring helps in early detection of potential issues, allowing for timely maintenance and reducing the risk of costly repairs.

Smart Sensors

Smart sensors are at the heart of IoT-enabled coating inspections. These sensors can detect changes in temperature, humidity, and other environmental factors that may affect the coating's performance.

Conclusion

The innovations in coating inspection technology are driving the industry towards greater efficiency and reliability. By embracing these advancements, businesses can enhance their operational capabilities and ensure the longevity of their assets.

Staying updated on these trends is crucial for industry professionals who aim to maintain competitive advantage and uphold the highest standards of quality and safety.