Comprehensive Guide to Coating Inspection Techniques

Understanding the Importance of Coating Inspection

Coating inspection is a crucial process in maintaining the longevity and effectiveness of protective coatings. These coatings serve as barriers against environmental factors, such as moisture, chemicals, and UV radiation. Ensuring their integrity is vital for the protection of structures and materials. Regular inspections help identify any potential failures or areas in need of repair, maintaining the coating's performance and, ultimately, the asset's lifespan.

Inspection techniques vary, each with its own set of tools and methodologies. Understanding these techniques can greatly enhance the effectiveness of your maintenance strategies.

Visual Inspection Techniques

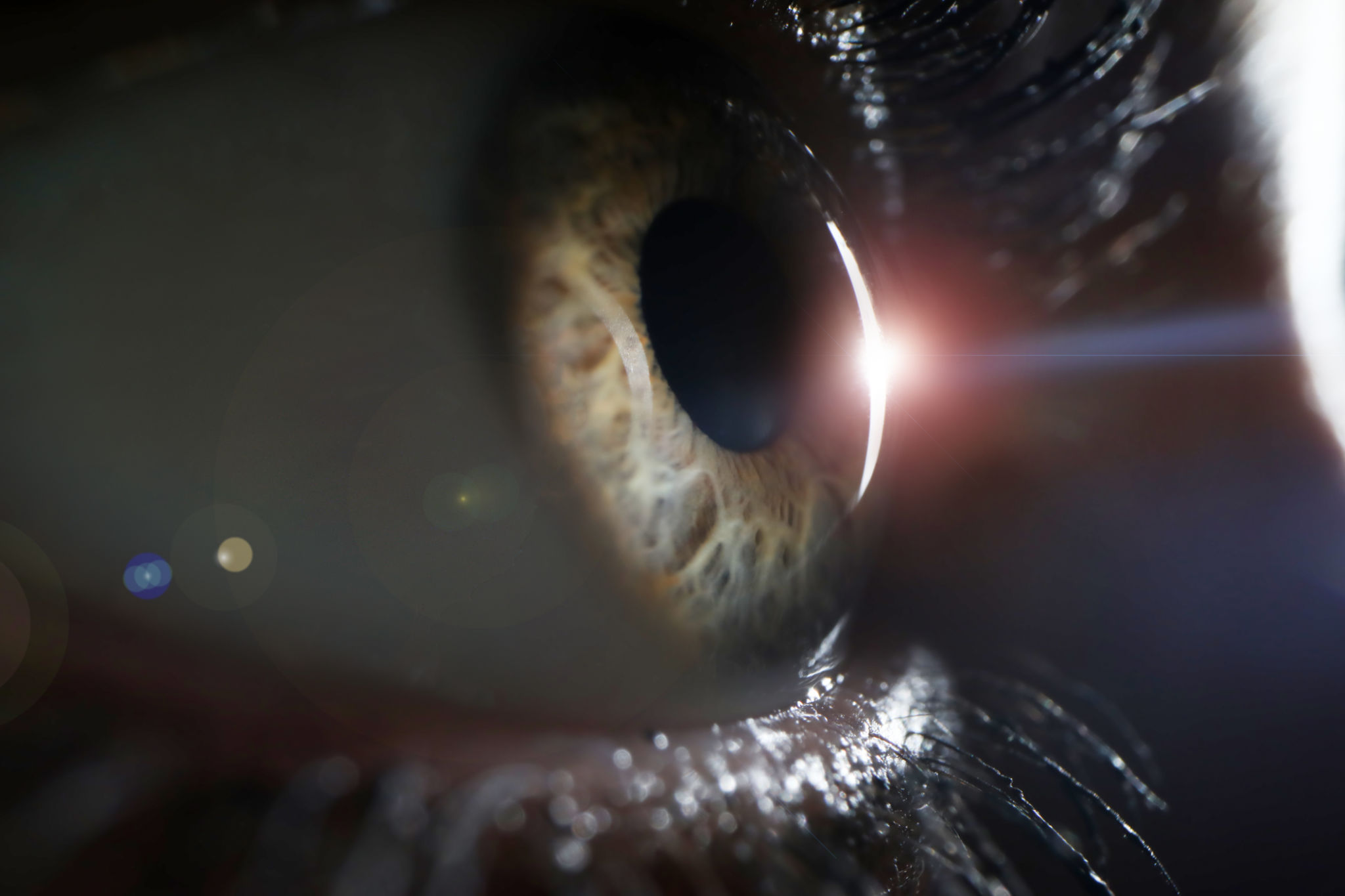

Visual inspection is often the first step in assessing a coating's condition. It involves a thorough examination of the surface to detect any visible defects such as cracks, blisters, or discoloration. These visual cues can indicate underlying issues that may require further investigation.

Inspectors use tools like mirrors, magnifying glasses, and even drones for hard-to-reach areas. Consistent visual inspections can help spot early signs of degradation, allowing for timely interventions.

Non-Destructive Testing (NDT) Methods

Non-destructive testing (NDT) methods are invaluable in coating inspection as they allow for thorough analysis without damaging the coating. Common NDT methods include ultrasonic testing, magnetic particle inspection, and eddy current testing. Each of these methods offers unique insights into the coating's thickness, adhesion, and overall integrity.

Ultrasonic testing, for example, uses high-frequency sound waves to measure coating thickness. This technique helps determine whether the coating is applied evenly and meets the specified thickness requirements.

Adhesion Testing Procedures

Adhesion testing is used to evaluate how well a coating adheres to its substrate. Poor adhesion can lead to premature coating failure. Two common methods are the pull-off test and the cross-cut test. The pull-off test measures the force required to remove the coating, while the cross-cut test involves cutting a pattern into the coating and evaluating how much of it remains intact.

These tests provide crucial data that can influence maintenance decisions and help ensure long-term coating performance.

Environmental Exposure and Its Impact

The environment plays a significant role in the performance of coatings. Factors such as humidity, temperature, and chemical exposure can affect the coating's durability. Inspectors often assess the environmental conditions during inspections to understand their impact on the coating's integrity.

Regular monitoring of these conditions can inform adjustments in maintenance schedules and strategies.

Documenting and Reporting Findings

Accurate documentation and reporting are essential components of coating inspections. Detailed reports should include findings from all inspection techniques, along with photographs and any relevant measurements. This information is crucial for tracking the coating's condition over time and planning future maintenance activities.

Modern software tools can streamline this process, offering digital solutions for data management and analysis.

Conclusion

Incorporating a comprehensive coating inspection strategy is essential for maintaining the effectiveness and durability of protective coatings. By utilizing various inspection techniques and documenting findings meticulously, businesses can prevent costly repairs and extend the life of their assets. Regular inspections are not just about compliance but are vital for proactive maintenance and asset management.